Not Only Detect Pinholes

| Model | SWASTIK |

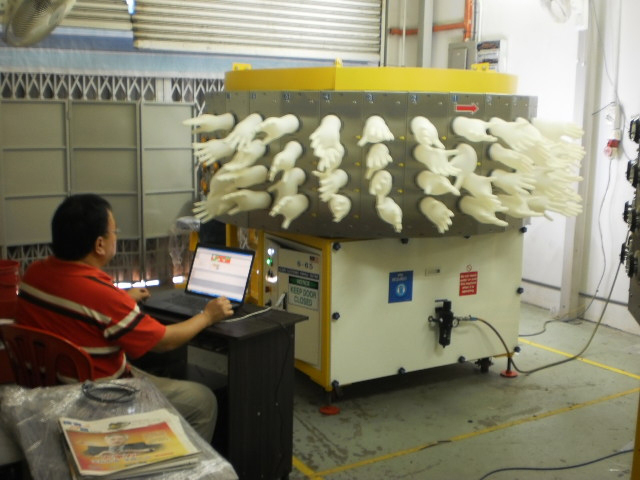

| Machine Capacity | Maximum 4600 Pieces/Hour |

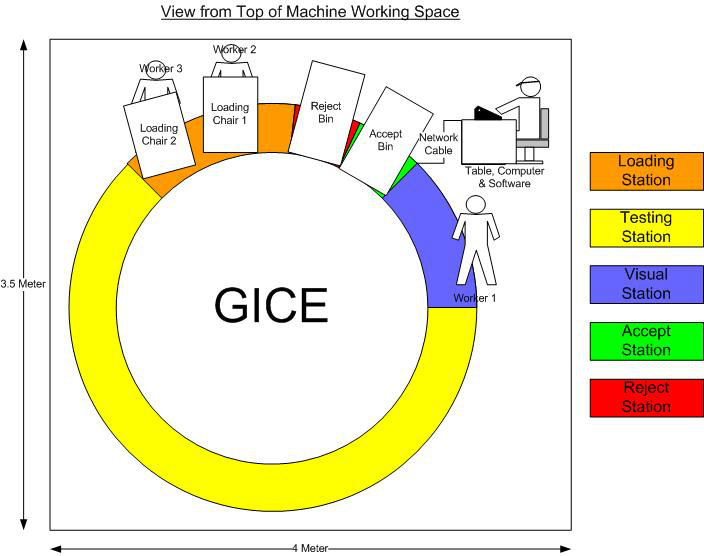

| Operators needed | Three(3) persons |

| Machine Dimensional Footprint | Area(3.5Mx4M),Height(2M) |

| Cycle Speed | Adjustable From 90 to 120 Seconds |

| Total Cup | 116 Cups |

| Software | Glove Tester Version 2 |

| Electricals | 415VAC/3Phase & 24VDC |

| Requirement | Dry Compressed Air |